When your customers see your printed products,they expect high standard one. This standard reflects the quality of your business,which ultimately affects the decision of the customer to either buy or move on to something else. Using a UV coating machines really helps your products shine and attract consumers’ attention. If you want your printings to stand out against the competitiors,you need to be aware of the best methods on the market today to make your printed products look professional, attractive and elegant.

UV coating machines,or Ultra-Violet coating systems, allow you to apply a very glossy and shiny coating to the surface of your printed paper,and then cured under UV light.

Once the special UV coating is exposed to UV light, it gets quickly cured and dry, allowing you to do the finish quickly and efficiently.

So what kind of products can be UV coated? There are many things that can benefit from a UV coating, making them more eye-catching to your customers. Some of the most common UV coating products include: paper/paperboard, PVC, PET, PE, PU, acrylic, glass, wood, metal, ceramics etc.

UV coating is one of the best methods available for finishing your products and making them look professional. This method has numerous advantages over other finishing methods commonly used in the world of business today. With UV coating products you get a very high shine finish, which is great for image-based products such as brochures, manu, photobook etc.

Another advantage of UV coated products is their resistance to abrasion, moisure or sunlight. If your products are going to be sent through the mail or handed out to customers, they need to able to resist wear and tear.

Our machines are mainly used for paper UV coating, album UV coating which plays a very important role on improving the printing quality.

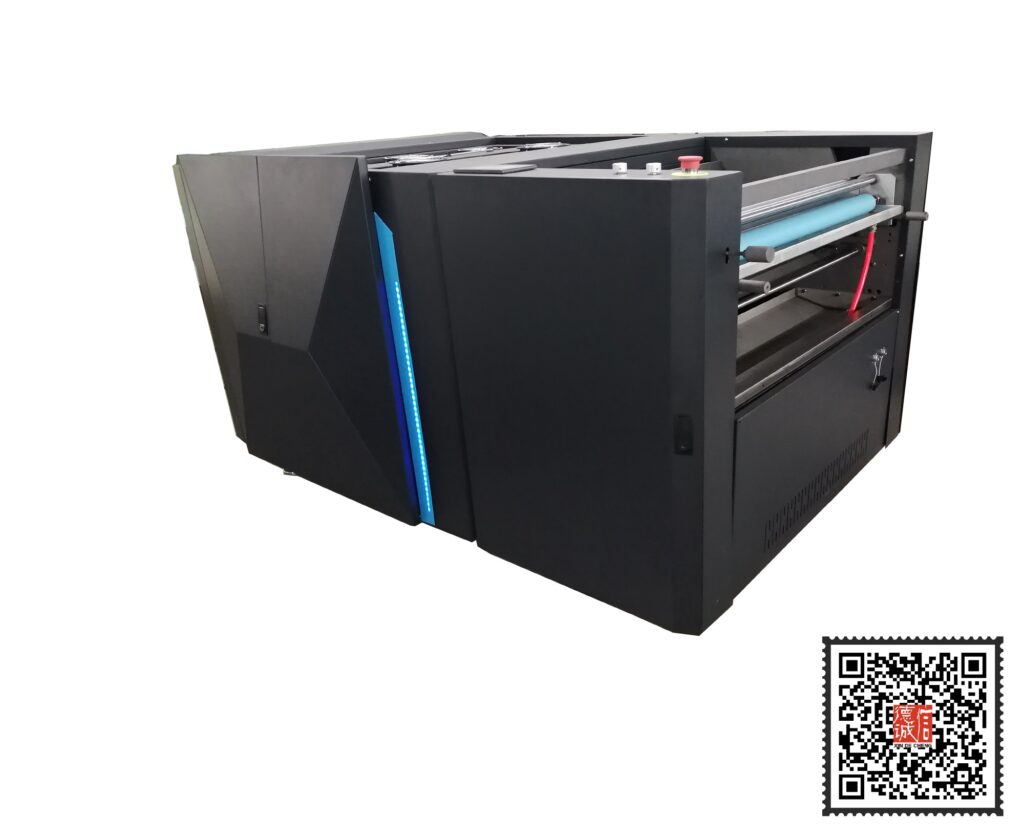

- Fully automatic UV and Aqueous coating machine XDC400A/XDC800A

- Manual feeding Roller UV Coating Machine XDC400/XDC800

- Rollfed UV & AQ Coating machine XDC330R

- Entry-level UV Coater machine XDC530E

- True Cold UV LED Coater LED360A

- Indigo Primer Coater XDC390P

- Automatic Flood UV Coater machine XDC390A

- Manual UV Varnishing machine XDC390

- Inkjet Spot UV Coater with Cold Foil JetTouch B2S

- Digital Inkjet 3D Spot UV and Digital Cold Foil Machine JetTouch B2D

- Inkjet Varnish UV Spot Coater with Cold Foil Embellishment JetTouch A3+

- Inkjet Enhancement Press with 3D UV and 3D Foil JetTouch B2

- Fully Automatic Die Cutting and Stripping Machine

- MY1080 Automatic Die Cutting and Creasing Machine